Twishimiye uburyo abakiriya bacu babyishimiye kandi bakabyakira neza kubera ko dukomeje gushaka ubwiza bwo hejuru haba ku bicuruzwa no gusana ku giciro gito mu Bushinwa ASME Standard B16.9 Eccentric Reducer hamwe n'icyuma gitemba, twakiranye ikaze inshuti zacu mu biganiro no gutangiza ubufatanye. Twifuza kwifatanya n'inshuti zacu mu nganda zitandukanye kugira ngo tugire ejo hazaza heza cyane.

Twishimiye uburyo abakiriya bacu babyishimiye kandi bakakirwa neza kubera ko dukomeza gushaka ibicuruzwa byiza ndetse no gusana ibicuruzwa byacu.Umushinwa ugabanya, Umuti ugabanya imiterere y'umubiri, Iyi kompanyi ifite urubuga rw'ubucuruzi mpuzamahanga, arirwo Alibaba, Globalsources, Global Market, Made-in-China. Ibicuruzwa bya "XinGuangYang" HID bigurishwa neza cyane mu Burayi, muri Amerika, mu Burasirazuba bwo Hagati n'ahandi mu bihugu birenga 30.

IBIPIMO BY'IBICURUZWA

| Izina ry'igicuruzwa | Imashini igabanya imiyoboro |

| Ingano | 1/2"-24" idafunze, ifite uburebure bwa 26"-110" ifunze |

| Igisanzwe | ANSI B16.9, EN10253-2, DIN2616, GOST17378, JIS B2313, MSS SP 75, n'ibindi. |

| Ubunini bw'urukuta | SCH5S, SCH10, SCH10S ,STD, XS, SCH40S, SCH80S, SCH20, SCH30, SCH40, SCH,60, SCH80, SCH160, XXS, byahinduwe n'ibindi. |

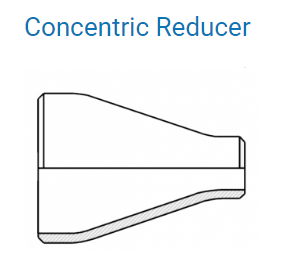

| Ubwoko | Ihuriro ry'ibintu bidasanzwe cyangwa bidasanzwe |

| Inzira | Idafite umushono cyangwa ivanze n'umushono |

| Iherezo | Impera y'umugongo/BE/ubuto |

| Ubuso | byashaje, bizunguruka umucanga, bisukuye, bisukura indorerwamo n'ibindi. |

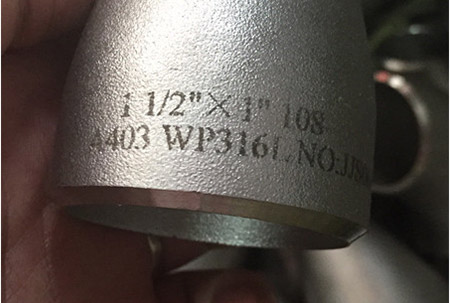

| Ibikoresho | Icyuma kidasembuye:A403 WP304/304L, A403 WP316/316L, A403 WP321, A403 WP310S, A403 WP347H, A403 WP316Ti, A403 WP317, 904L, 1.4301,1.4307,1.4401,1.4571,1.4541, 254Mo n'ibindi. |

| Ibyuma bibiri bitagira umugese:UNS31803, SAF2205, UNS32205, UNS31500, UNS32750, UNS32760, 1.4462,1.4410,1.4501 n'ibindi. | |

| Ingano ya nikeli:inconel600, inconel625, inconel690, incoloy800, incoloy 825, incoloy 800H, C22, C-276, Monel400, Alloy20 n'ibindi. | |

| Porogaramu | Inganda za peteroli; inganda z'indege n'indege; inganda z'imiti, imyuka ihumanya ikirere; uruganda rw'amashanyarazi; inyubako y'amato; gutunganya amazi, n'ibindi. |

| Ibyiza | Ibicuruzwa byiteguye, igihe cyo kubigeza vuba; biraboneka mu bunini bwose, byahinduwe; bifite ireme ryo hejuru. |

IMIKORESHEREZE Y'ICUMA GIGABANYIJE IMIYOBORO Y'ICUMA

Ikoreshwa ry'icyuma gigabanya ubushyuhe rikorerwa mu nganda zikora imiti n'ingufu. Rituma uburyo bwo gukwirakwiza imiyoboro bwizewe kandi buto. Ririnda uburyo bwo gukwirakwiza imiyoboro ingaruka mbi cyangwa impinduka mbi z'ubushyuhe. Iyo iri ku ruziga rw'umuvuduko, irinda ubwoko ubwo aribwo bwose bw'amazi kandi biroroshye kuyishyiraho. Udukoresho duto dukozwe muri nikeli cyangwa chrome twongera igihe cyo kubaho k'umusaruro, tukaba ingirakamaro ku miyoboro myinshi y'umwuka, kandi tukarinda ingese.

UBWOKO BW'IBIGABANYIJWE

Udukoresho duto dukoreshwa cyane mu gihe udukoresho duto dukoreshwa mu buryo budasanzwe kugira ngo umuyoboro wo hejuru n'uwo hasi ugume uringaniye. Udukoresho duto dukoreshwa mu buryo budasanzwe kandi twirinda gufata umwuka mu muyoboro, kandi utwo dukoresho duto dukoreshwa mu buryo burambye tugabanya urusaku.

UKORA UMURIRO W'ICUMA GIGABANYIJE IMIYOBORO Y'ICUMA

Hari uburyo butandukanye bwo gukora ibikoresho bigabanya umuriro. Ibi bikorwa mu miyoboro ivanze n'ibikoresho byuzuza bikenewe. Ariko, imiyoboro ya EFW na ERW ntishobora gukoresha ibikoresho bigabanya umuriro. Mu gukora ibice bicuzwe, hakoreshwa uburyo butandukanye burimo uburyo bukonje n'ubushyuhe.

AMAFOTO YIMBITSE

1. Umwanya w'inyuma nk'uko bivugwa muri ANSI B16.25.

2. Banza ushushanye neza mbere yo gushushanya umucanga, hanyuma ubuso buzaba bworoshye cyane.

3. Nta gufunga no gucikamo ibice.

4. Nta gusana ibikoresho byo gusudira.

5. Gutunganya ubuso bishobora gukurwamo ibinyampeke, gushonga umucanga, kurangizwa na matte, gusiga indorerwamo. Nta gushidikanya ko igiciro gitandukanye. Ku bwawe, ubuso bwo gushonga umucanga ni bwo buzwi cyane. Igiciro cyo gushonga umucanga gikwiriye abakiriya benshi.

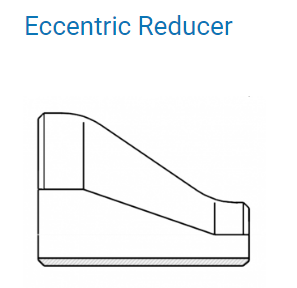

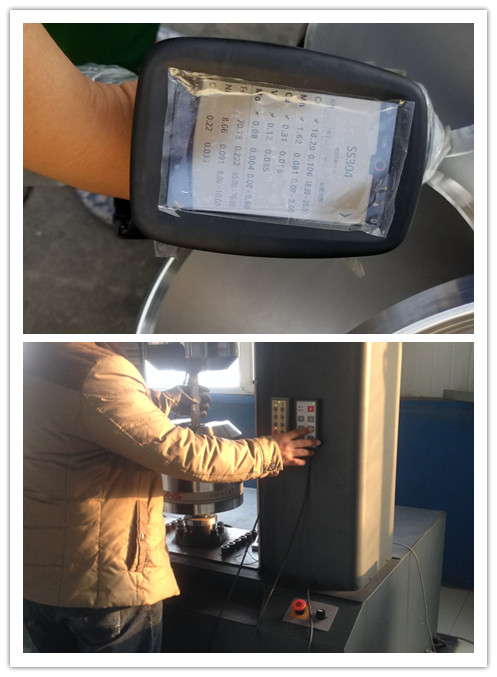

IGENZURA

1. Ibipimo by'ingano, byose biri mu buryo busanzwe bwo kwihanganira.

2. Kwihanganira ubunini: +/-12.5%, cyangwa ubisabye.

3. PMI

4. Ikizamini cya PT, UT, X-ray.

5. Emera isuzuma ry'umuntu wa gatatu.

6.Gutanga MTC, icyemezo cya EN10204 3.1/3.2, NACE

7. ASTM A262 imyitozo E

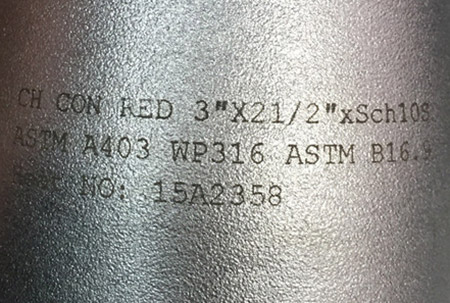

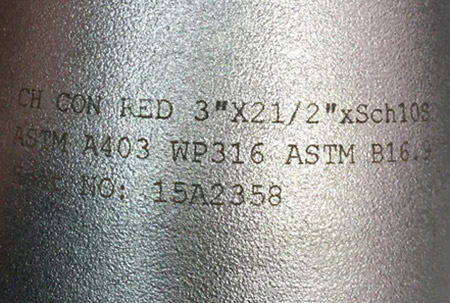

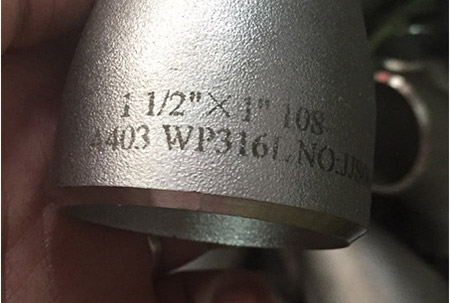

IKIMENYETSO

Ushobora gukora akazi gatandukanye ko gushyira ikimenyetso ku nyuguti zawe. Twemera ikimenyetso cyawe.

GUPAKA NO KOHEREZA

1. Ipakiye mu gasanduku ka plywood cyangwa palati ya plywood.

2. Tuzashyira urutonde rw'ibipaki kuri buri paki.

3. Tuzashyira ibimenyetso byo kohereza kuri buri paki. Amagambo y'ibimenyetso ni ayo usabye.

4. Ibikoresho byose bipakiye mu mbaho ntibikoreshwa mu gutwika.

Twishimiye uburyo abakiriya bacu babyishimiye kandi bakabyakira neza kubera ko dukomeje gushaka ubwiza bwo hejuru haba ku bicuruzwa no gusana ku giciro gito mu Bushinwa ASME Standard B16.9 Eccentric Reducer hamwe n'icyuma gitemba, twakiranye ikaze inshuti zacu mu biganiro no gutangiza ubufatanye. Twifuza kwifatanya n'inshuti zacu mu nganda zitandukanye kugira ngo tugire ejo hazaza heza cyane.

Igiciro cyo hasi cya China Reducer, Eccentric Reducer, Iyi sosiyete ifite urubuga rw'ubucuruzi mpuzamahanga, arirwo Alibaba, Globalsources, Global Market, Made-in-China. Ibicuruzwa bya "XinGuangYang" HID bigurishwa neza cyane mu Burayi, muri Amerika, mu Burasirazuba bwo Hagati n'ahandi mu bihugu birenga 30.

Ikoreshwa ry'icyuma gigabanya ubushyuhe rikorerwa mu nganda zikora imiti n'ingufu. Rituma uburyo bwo gukwirakwiza imiyoboro bwizewe kandi buto. Ririnda uburyo bwo gukwirakwiza imiyoboro ingaruka mbi cyangwa impinduka mbi z'ubushyuhe. Iyo iri ku ruziga rw'umuvuduko, irinda ubwoko ubwo aribwo bwose bw'amazi kandi biroroshye kuyishyiraho. Udukoresho duto dukozwe muri nikeli cyangwa chrome twongera igihe cyo kubaho k'umusaruro, tukaba ingirakamaro ku miyoboro myinshi y'umwuka, kandi tukarinda ingese.

Udukoresho duto dukoreshwa cyane mu gihe udukoresho duto dukoreshwa mu buryo budasanzwe kugira ngo umuyoboro wo hejuru n'uwo hasi ugume uringaniye. Udukoresho duto dukoreshwa mu buryo budasanzwe kandi twirinda gufata umwuka mu muyoboro, kandi utwo dukoresho duto dukoreshwa mu buryo burambye tugabanya urusaku.

Hari uburyo butandukanye bwo gukora ibikoresho bigabanya umuriro. Ibi bikorwa mu miyoboro ivanze n'ibikoresho byuzuza bikenewe. Ariko, imiyoboro ya EFW na ERW ntishobora gukoresha ibikoresho bigabanya umuriro. Mu gukora ibice bicuzwe, hakoreshwa uburyo butandukanye burimo uburyo bukonje n'ubushyuhe.

Amafoto arambuye

1. Umwanya w'inyuma nk'uko bivugwa muri ANSI B16.25.

2. Banza ushushanye neza mbere yo gushushanya umucanga, hanyuma ubuso buzaba bworoshye cyane.

3. Nta gufunga no gucikamo ibice.

4. Nta gusana ibikoresho byo gusudira.

5. Gutunganya ubuso bishobora gukurwamo ibinyampeke, gushonga umucanga, kurangizwa na matte, gusiga indorerwamo. Nta gushidikanya ko igiciro gitandukanye. Ku bwawe, ubuso bwo gushonga umucanga ni bwo buzwi cyane. Igiciro cyo gushonga umucanga gikwiriye abakiriya benshi.

Igenzura

1. Ibipimo by'ingano, byose biri mu buryo busanzwe bwo kwihanganira.

2. Kwihanganira ubunini: +/-12.5%, cyangwa ubisabye.

3. PMI

4. Ikizamini cya PT, UT, X-ray.

5. Emera isuzuma ry'umuntu wa gatatu.

6.Gutanga MTC, icyemezo cya EN10204 3.1/3.2, NACE

7. ASTM A262 imyitozo E

Gushyira ikimenyetso

Ushobora gukora akazi gatandukanye ko gushyira ikimenyetso ku nyuguti zawe. Twemera ikimenyetso cyawe.

Gupakira no Kohereza

1. Ipakiye mu gasanduku ka plywood cyangwa palati ya plywood.

2. Tuzashyira urutonde rw'ibipaki kuri buri paki.

3. Tuzashyira ibimenyetso byo kohereza kuri buri paki. Amagambo y'ibimenyetso ni ayo usabye.

4. Ibikoresho byose bipakiye mu mbaho ntibikoreshwa mu gutwika.

Ibikoresho by'imiyoboro ni ingenzi cyane mu miyoboro, bikoreshwa mu guhuza, kuyobora, guhindura ingano, gufunga cyangwa kugenzura urujya n'uruza rw'amazi. Bikoreshwa cyane mu nzego nko mu bwubatsi, mu nganda, mu ngufu no mu nzego z'umujyi.

Imirimo y'ingenzi:Ishobora gukora imirimo nko guhuza imiyoboro, guhindura icyerekezo cy'amazi, kugabanya no guhuza amazi atemba, guhindura uburebure bw'imiyoboro, gufunga imiyoboro, kugenzura no kugenzura.

Ingano y'Ikoreshwa:

- Imiyoboro y'amazi n'imiyoboro y'amazi mu nyubako:Inkokora za PVC na PPR tris bikoreshwa mu miyoboro y'amazi.

- Imiyoboro y'inganda:Udupira tw'icyuma kidashonga n'inkokora z'icyuma gikozwe mu byuma bikoreshwa mu gutwara ibikoresho by'ubutabire.

- Ubwikorezi bw'ingufu:Imiyoboro y'icyuma ifite umuvuduko mwinshi ikoreshwa mu miyoboro ya peteroli na gaze.

- HVAC (Ubushyuhe, Guhumeka, n'Ubukonjesho bw'Umwotsi):Ibikoresho by'imiyoboro y'umuringa bikoreshwa mu guhuza imiyoboro ikora muri firigo, naho ingingo zoroshye zikoreshwa mu kugabanya gutigita.

- Kuhira imyaka mu buhinzi:Ibikoresho byihuse byoroshya guteranya no gusenya uburyo bwo kuhira imiyoboro y'amazi.

-

igiciro cyo kugurisha mu bucuruzi bw'ibirahuri by'icyuma gitembabuzi cy'Ubushinwa SS3 ...

-

Ifite umugongo utagira umushongi wa dogere 90, ifite umugongo utagira umushongi, ivanze n'icyuma gifunganye ...

-

Karuboni y'Abashinwa y'inzobere mu Bushinwa ya ANSI/DIN Forged Carb...

-

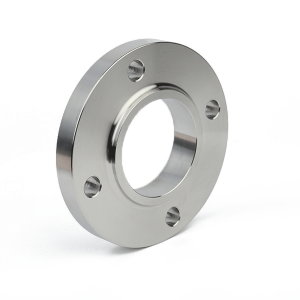

Igiciro gihoraho cyo gupiganwa mu Bushinwa ANSI B16.5 Slip o ...

-

Flange y'Ubushinwa yo Kugurisha Isoke yo mu Bushinwa

-

OEM/ODM Ubushinwa Ubushinwa ANSI B16.5 Grade 2 150# Pres...